September 5, 2025 news

Moving bulk materials in tight spaces and over long distances? Essmueller’s chain conveyors—also known as drag conveyors, and en-masse conveyors—stand out as a very dependable, low-maintenance solution. Widely used in grain handling, feed milling, wood pelleting, ethanol production and oil seed crushing, these systems are specifically designed to convey en-masse, a process that maximizes material throughput while minimizing energy consumption and product degradation.

En-masse conveying refers to the movement of material in a solid, continuous stream—essentially “mass moving as one”—through a dust-tight casing. This is made possible by a chain and flights that drag the material through the conveyor’s trough at a relatively low speed. This results in low turbulence, less dust, and reduced wear and tear on both the equipment and the product.

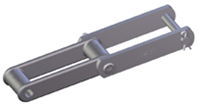

At the core of the chain conveyor is a heavy-duty, endless chain equipped with flights or paddles. These components move through a fully enclosed trough, dragging the bulk material along to a point of discharge.

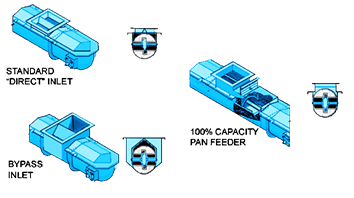

The drag conveyor chain moves the material on the bottom and the “shear strength” or “friction” of the material carries additional material above in a quiescent column maximizing the conveyor cross section. (see illustration)

This design ensures the bulk material is captured and moves as a continuous column to maximize conveyor capacity. Their enclosed design makes them ideal for handling hazardous or dusty materials in a controlled environment, making them ideal in a grain facility or feed mill.

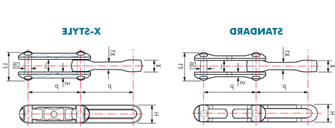

(Various drag chain styles)

Components are selected using a variety of criteria such as required chain working tension, abrasiveness of the application, corrosion likelihood, or even food grade needs. Essmueller’s team can work through the necessary calculations and application evaluation to ensure the proper setup is selected.

One of the biggest advantages of drag chain conveyors is durability. With fewer moving parts and an uncomplicated design, they offer long service life and minimal maintenance. As with any piece of machinery, regular inspections of all components and proper lubrication are required for long life. The chain and drag paddles are common parts susceptible to wear. Proper chain tensioning is required to keep them running smoothly.

If your operation involves bulk materials, requires dust control, or demands high efficiency in compact layouts, chain conveyors for en-masse conveying might be the ideal solution. Their adaptability and low operational cost make them a smart long-term investment.

Choosing the right conveyor system is about more than moving material—it is about optimizing your entire operation. Chain conveyors for en-masse conveying offer a compelling blend of efficiency, durability, and cleanliness, making them an industry staple, and Essmueller’s design a favorite for a reason.

© 2025 Essmueller Co. All rights reserved. Site Design by Brand Neue Co.