“RB” Round-Bottom Drag-Flite

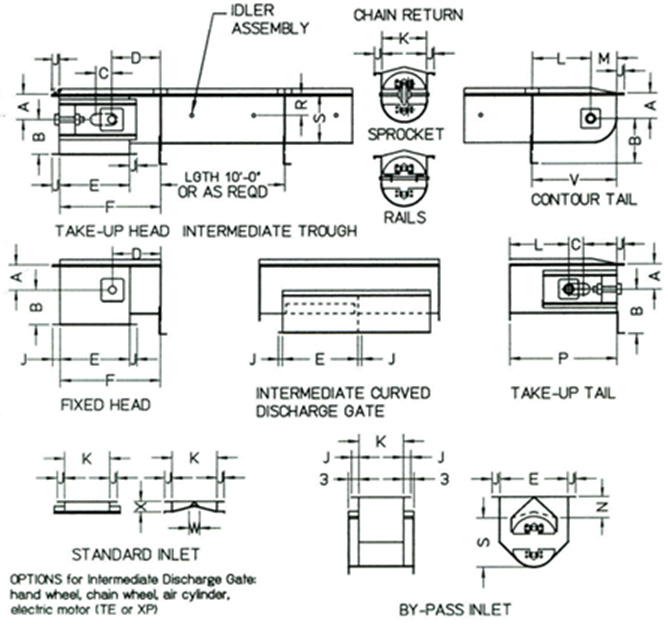

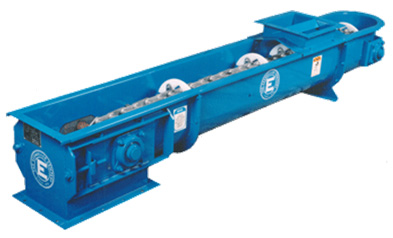

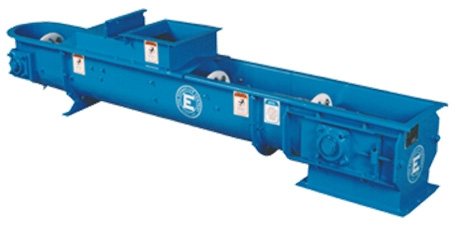

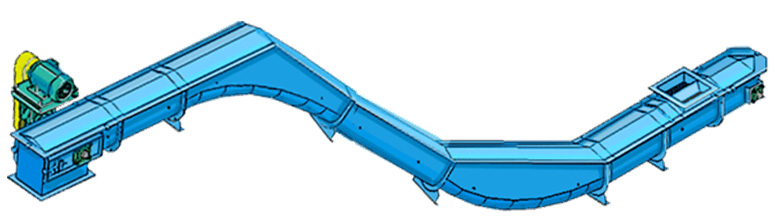

Round Bottom Conveyors are designed to operate horizontally or at inclines up to 45° (some material to 60°) with one or two bend sections. An internal “shroud” may be required with some materials at inclines above 14°. A reverse-incline bend section is generally required when the head section is at an angle above 45°.

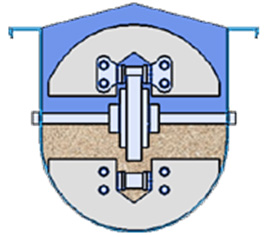

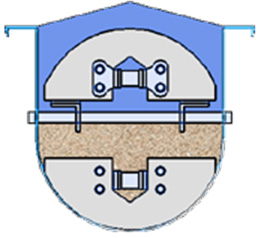

Sizes: 6” – 24”, (nominal trough width) attain capacities up to 20,650 bushels (25,812 cubic feet) per hour. The principle advantage of the Round Bottom conveyor is its “High Efficiency” clean out and a reduction in carry-over. Close tolerance in the contoured tail section along with the shape and fit of the flights in the trough ensures minimal amounts of material remain in the conveyor between batches. The Round Bottom conveyors clean-out efficiency is greater than that of a screw conveyor, and requires less horsepower to operate. No type of singe-chain conveyor can promise 100% clean-out under all conditions, but Round Bottom conveyors are more effective than other chain conveyors.